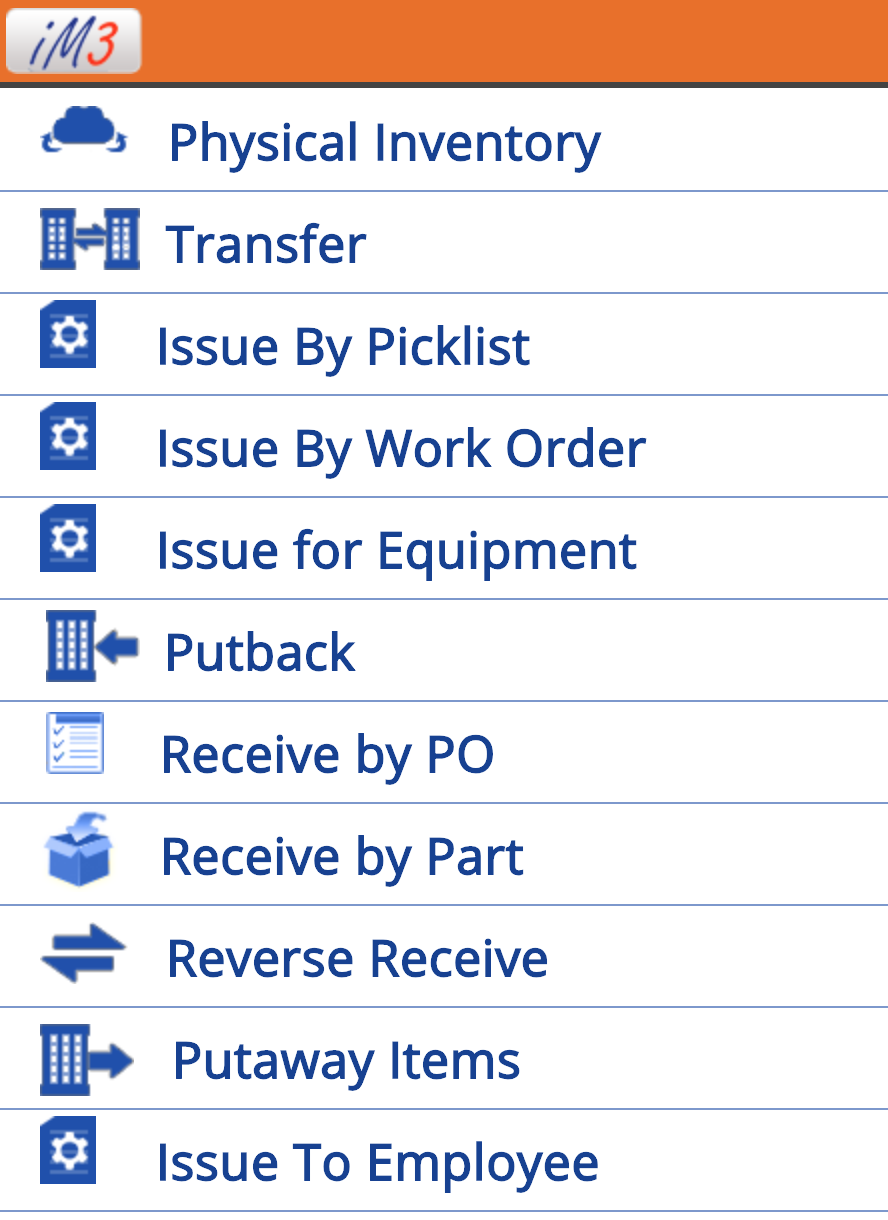

Warehouse Pilot

Manage your internal warehouse operations with a device of your choice. Our application is integrated with the latest robust mobile computer warehouse scanners, Apple iOS tablets and smartphones, and Android tablets and smartphones. We are also partners/resellers with Zebra and Honeywell, please visit our barcodes hardware pages found under the products and services tab for more information (insert link to barcode scanners).

Physical Inventory

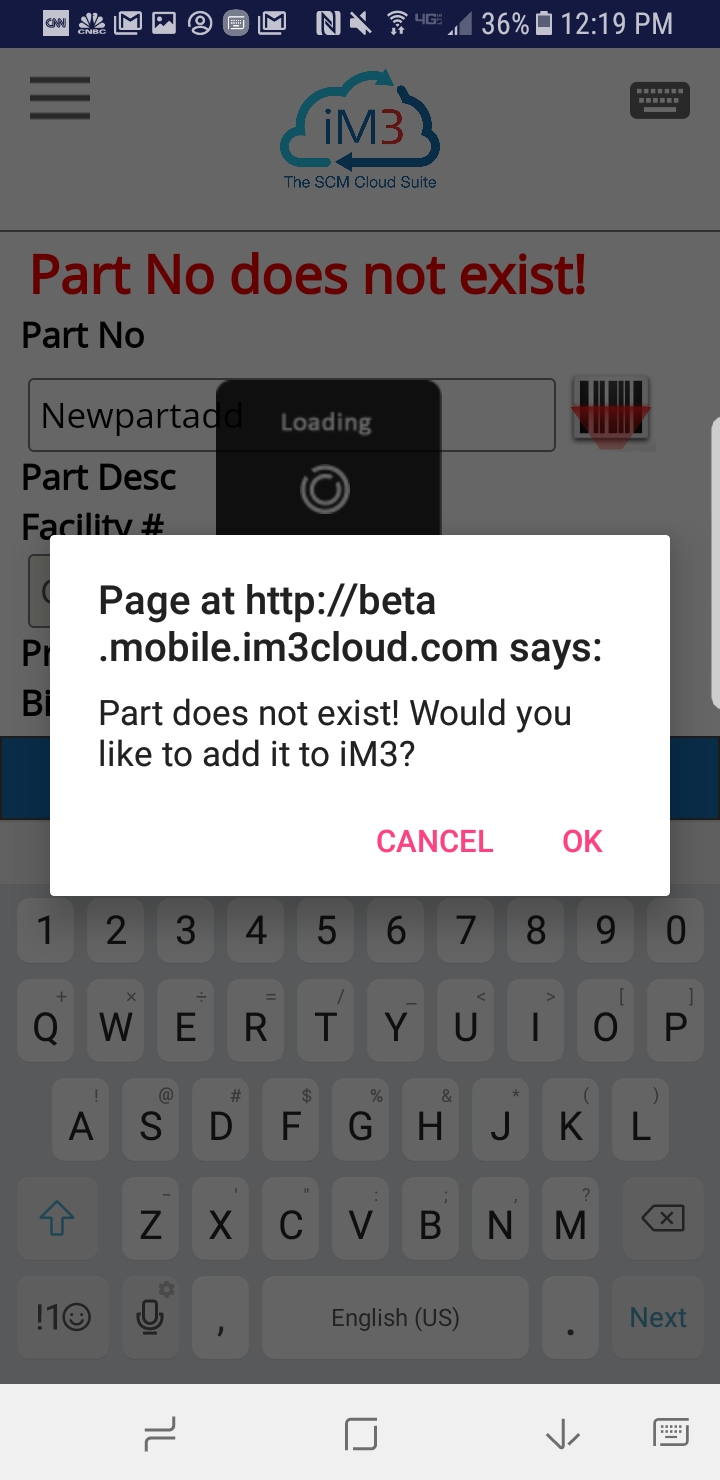

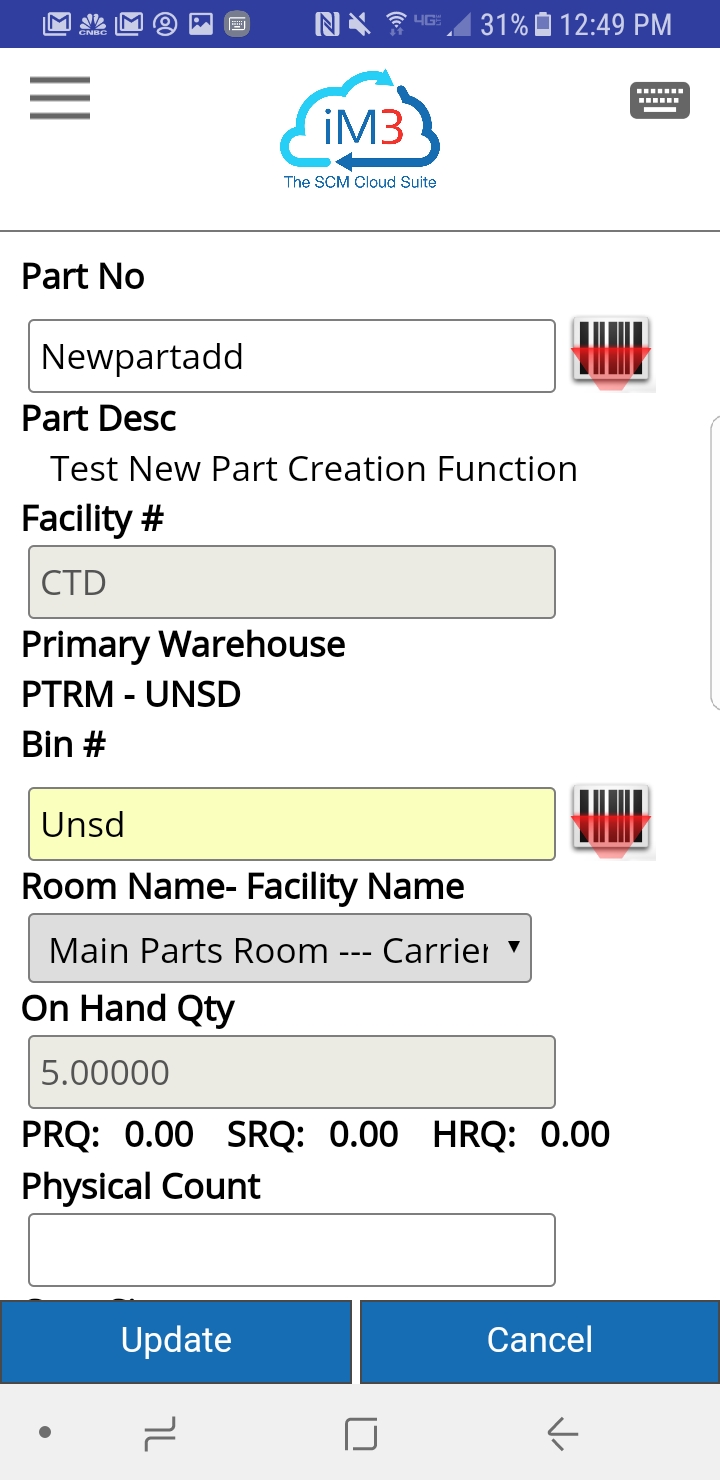

Whether you’re performing a physical end of the year inventory or a cycle count our inventory counting program allows you to update your inventory in real-time integrated with the iM3 SCM Cloud’s item master. We work with you to barcode your entire warehouse with product and location labels, which make counting quick and efficient. With a minimum of two scans you can update the inventory for a product and move on to the next part. Unlimited logins and team members can be simultaneously updating the inventory together. The physical inventory program also allows you to add new parts. If the part that is scanned is not recognized from your entire part master, the program automatically notifies you that this part does not exist and asks if you would like to add it.

Issue by Picklist/Issue By Work Order

Mistakes in inventory occur in two key warehouse functions: 1). Picking and during 2). Receiving. Using the issue by picklist and work order programs, ensure that any inventory leaving your warehouse either on a Sales Order or Work Order (repair order) are scanned and “issued” on to the transaction depleting your inventory. This step ensures inventory is maintained live and accurate as several hundreds of transactions or warehouse functions can be performed at the same time by other users. Through the mobile application or scanner mode, you can easily scan parts on to the document of the transaction (either scan the barcode on the physical hardcopy or go paperless and scan from your computer work station).

Putaway Items

Putting away items are an essential function of your warehouse processes. When items are received at your facility in bulk, it is important to have a strategy in place on how the increased value and number to your inventory will be reflected and made available to be used for your company. Often times many warehouse or parts managers prefer to directly putaway items to the exact putaway location that particular part belongs to upon receive. However, this is where your inventory can become inaccurate due to human error. It is important to ensure that a part has been putaway to the location that is defined as it’s putaway location. Often times, a part can be putaway at an entirely different location making it impossible to locate and extremely crucial to use a program that detects where the part was stored or scanned away at. You can also set your parts to receive at docking location or an imaginary “made up” location (for example: wall, floor, receiving station, dock) where you can organize your shipments and parts by categories.

Receive by PO/Part

For some particular orders, typically smaller orders, it is easier to receive those parts or orders individually. Either by the Purchase Order or a specific part. You can use the receive by PO/part program to do this. These parts will receive directly to the putaway location based on their setup in Inventory master.

Transfer

Often times you need a quick function or program to transfer parts between bin locations in the same warehouse, different facility, to your service trucks, etc. Using the transfer program you can quickly perform this